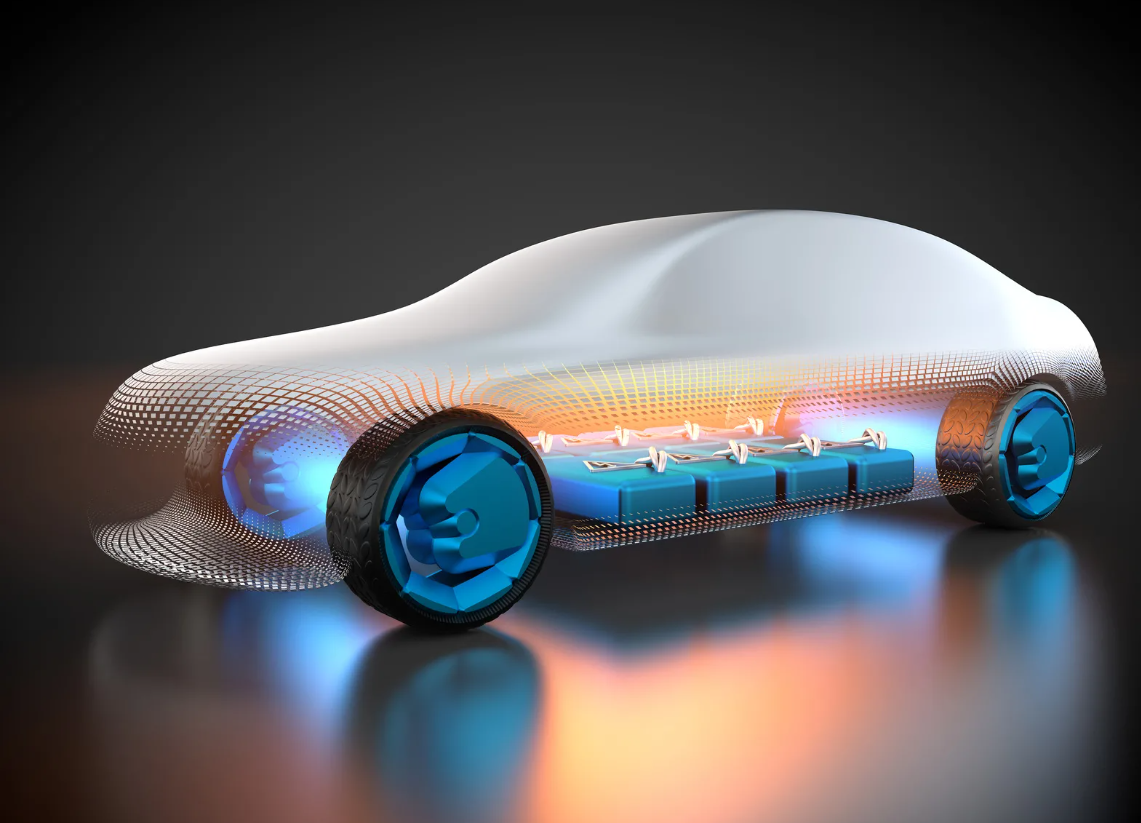

The electric vehicle battery adhesive market is poised for substantial growth in the coming years. As the electric vehicle industry continues to expand, driven by environmental concerns, government policies, and advancements in battery technologies, the demand for high-performance adhesives in battery packs is expected to rise. The adhesives play a crucial role in securing battery components, improving thermal management, and enhancing overall battery safety and performance. The market forecast predicts a steady upward trajectory, driven by these key developments and increasing global EV adoption.

1. Increasing EV Adoption and Demand for Battery Solutions

- The global electric vehicle market is expected to grow at a compound annual growth rate (CAGR) of over 20% by 2030.

- Increased consumer preference for EVs, coupled with supportive government policies, is driving demand for battery solutions, thereby increasing the need for specialized adhesives.

- Rising oil prices and concerns over climate change are also motivating consumers and governments to switch to electric mobility.

2. Technological Advancements in Battery Chemistry

- The development of next-generation batteries such as solid-state and lithium-sulfur batteries is expected to fuel demand for advanced adhesives that can handle higher temperatures and provide better structural integrity.

- Adhesives that offer enhanced thermal management and durability will become critical as battery technologies evolve.

- New formulations, such as thermally conductive adhesives, will be essential for the growing demand in high-performance battery packs.

3. Demand for Lightweight Components in EV Manufacturing

- Adhesives offer a lightweight alternative to traditional fasteners, which aligns with the automotive industry's push to reduce vehicle weight and increase energy efficiency.

- As automakers focus on reducing the overall weight of EVs, battery adhesives will continue to see strong demand for both cell bonding and structural bonding applications.

- Lightweight adhesives help enhance the driving range of EVs by lowering vehicle weight without compromising structural integrity.

4. Stringent Safety Regulations Driving Adhesive Innovation

- EV batteries are critical for ensuring the safety and reliability of electric vehicles, and adhesives are instrumental in meeting safety standards.

- The need for fire-resistant, impact-resistant, and high-performance adhesives will continue to grow as regulations around battery safety become more stringent.

- Battery adhesive suppliers will focus on meeting the latest regulatory requirements by providing adhesives that ensure minimal risk of battery failure and overheating.

5. Regional Market Outlook and Growth Projections

- The Asia-Pacific region is expected to lead the market due to the dominance of EV production in countries like China, Japan, and South Korea.

- North America and Europe are witnessing steady growth due to increasing electric vehicle adoption, especially with the launch of new EV models and strong infrastructure investments.

- The rise of EV production hubs in countries like India, which are anticipated to become key players in the EV landscape, will further boost demand for electric vehicle battery adhesives in the coming years.

6. Increasing Focus on Sustainability and Eco-friendly Adhesive Solutions

- Manufacturers are increasingly investing in the development of eco-friendly adhesives, which are aligned with global sustainability goals.

- There is growing demand for adhesives that not only perform well but also have a minimal environmental footprint, thus driving market growth.

- Bio-based adhesives and those with reduced volatile organic compound (VOC) emissions will play an important role in shaping the future of the electric vehicle battery adhesive market.

7. Competitive Landscape and Key Players

- Leading players such as Henkel, 3M, Dow Chemical, and H.B. Fuller are driving market innovation by investing heavily in R&D and launching new adhesive products.

- These companies are focusing on improving adhesive properties like curing time, flexibility, and thermal stability, essential for the evolving needs of EV battery technology.

- Strategic partnerships between adhesive manufacturers and automakers are becoming increasingly common, enabling the development of tailored adhesive solutions to meet specific performance requirements.

8. Market Challenges and Barriers

- Despite the forecasted growth, the high cost of high-performance adhesives may act as a barrier for widespread adoption in budget-friendly EV models.

- Material compatibility remains a challenge, as adhesives must be compatible with various materials used in battery construction to ensure optimal performance.

- Regulatory hurdles, such as the need for adhesives to meet environmental and safety standards across different regions, can slow market growth in some areas.

9. Market Forecast and Future Growth Potential

- The electric vehicle battery adhesive market is expected to grow at a robust CAGR over the next decade, driven by the increasing adoption of EVs and the continuous innovation in battery technologies.

- Market players will focus on developing adhesives with faster curing times, superior thermal stability, and greater compatibility with new battery designs.

- The transition to sustainable transportation and the increasing focus on reducing carbon emissions will be major contributors to the market's future growth.