3D printing has revolutionized manufacturing and prototyping, but it is not without its challenges. In this article, we will delve into 3D printing troubleshooting: 15 most common problems & solutions to help you navigate the complexities of this technology.

Understanding Common 3D Printing Issues

When engaging with 3D printing, users often encounter various issues that can hinder the printing process. Below, we outline the most prevalent problems and their respective solutions.

- Filament Not Extruding: This can occur due to a clogged nozzle or incorrect temperature settings. Ensure your nozzle is clean and the temperature is set according to the filament specifications.

- Layer Separation: This issue arises when layers do not adhere properly. Increasing the print temperature or adjusting the print speed can help.

- Warping: Warping typically occurs with ABS filament. Using a heated bed and applying adhesive can mitigate this problem.

- Stringing: Excess filament can create unwanted strings between parts. Adjusting retraction settings can significantly reduce stringing.

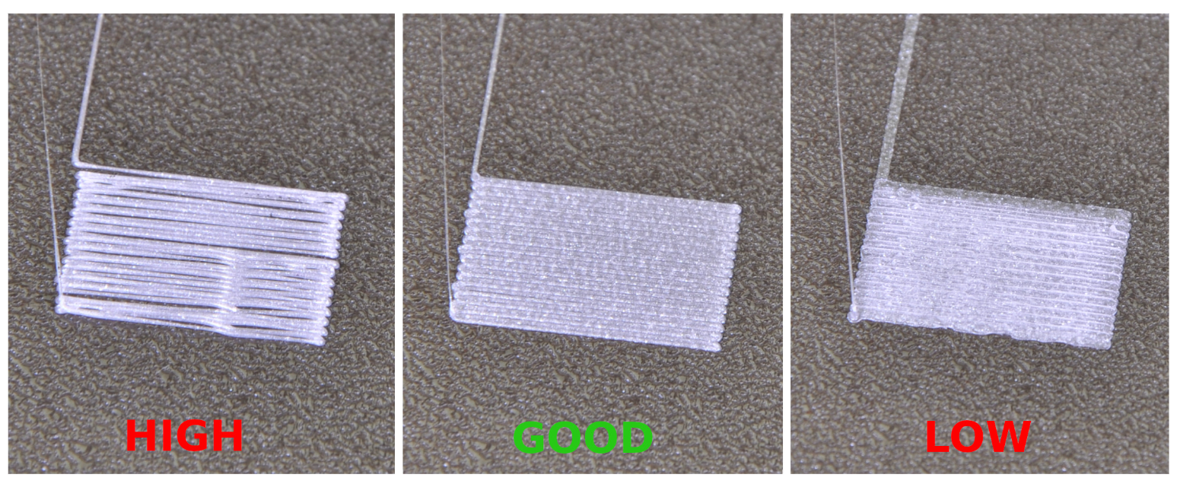

- Under-extrusion: This happens when the printer does not extrude enough filament. Check for clogs and ensure the filament diameter is correct.

- Over-extrusion: Too much filament can lead to blobs and zits on the print. Reducing the flow rate can resolve this issue.

- Print Not Sticking to the Bed: This can be addressed by leveling the bed and using adhesion aids like glue sticks or painter's tape.

- Layer Misalignment: This often results from mechanical issues. Check the belts and pulleys for wear and ensure they are properly tensioned.

- Ghosting or Ringing: This is caused by vibrations during printing. Reducing print speed and ensuring a stable printer setup can help.

- Color Inconsistencies: Different batches of filament can vary in color. Mixing filaments from the same manufacturer can help maintain consistency.

- Failed Prints: Regularly monitor your prints and adjust settings as needed to prevent failures.

- Overheating: If your printer is overheating, consider improving ventilation or adjusting the cooling settings.

- Print Quality Issues: Regular maintenance of your printer, including cleaning and lubrication, can enhance print quality.

- Software Errors: Ensure your slicing software is up to date and configured correctly for your printer.

- Material Compatibility: Not all filaments work with every printer. Always check compatibility before purchasing.

Practical Solutions for Effective 3D Printing Troubleshooting

To effectively tackle these issues, consider the following practical solutions:

- Regularly maintain your printer to prevent mechanical failures.

- Keep your workspace clean to avoid contamination of materials.

- Invest in quality filaments to ensure better print outcomes.

- Utilize online communities for troubleshooting advice and support.

"3D printing troubleshooting: 15 most common problems & solutions is essential for anyone looking to enhance their printing experience." - 3D Printing Expert

Conclusion

In conclusion, understanding the 3D printing troubleshooting: 15 most common problems & solutions can significantly improve your printing experience. By being aware of these common issues and their solutions, you can minimize downtime and enhance the quality of your prints. For more detailed insights, consider exploring resources such as 3D Printing.

References

Your browser does not support the video tag.

Your browser does not support the video tag.